New NESHAP 6-H RULE – Paint Stripping and Various Spraying Operations

The National Emissions Standard for Hazardous Air Pollutants (NESHAP) is the air quality division of the United States Environmental Protection Agency (EPA). NESHAP defined new air quality requirements for surface coating and paint stripping operations in 2008. It becomes enforceable at the end of 2010. This new rule defines a form that has to be submitted for new or modified spray and stripping operations for vehicles and mobile equipment. The forms and requirements are available on-line through your local EPA office at https://www.epa.gov/. Continue reading Be Advised – The New NESHAP rules could affect your business!!

Category: Tools USA

Going “GREEN” – Our History and Getting Started in Your Shop

Have you every built a deck, a table or a fence only to find out that you wasted 30, 40, or even 50% of the material purchased due to poor planning and design?

Standard Tools and Equipment Co. has been making collision repair equipment, spray booths and dust collectors since 1979. We have refined our processes and equipment to result in a waste level of only 7%. Scrap steel is sent back to the mill to be processed into new steel; scrap wood is ground up by a recycler for use in chipboard products; and hazardous wastes are processed by federal government-approved waste handlers.

Continue reading Going “GREEN” – Our History and Getting Started in Your Shop

Another Load of Frame Machines Leaves the Plant!

Autobody Equipment Financing

Tools USA now offers financing on a paint booth, frame machine or multi item purchases! To take advantage of our new program, please call 800-451-2425.

To be approved for the financing, qualified customers must meet the following criteria: 1. located in EST zone, 2. acceptable credit, 3. agree to ACH monthly drafts, 4. minimum of 40% down payment, and 5. must finance $3000 which would require an order of $5000.

Financing rates will be between 10-14% with 24, 36, and 48 month lease options with a $1 buy-out.

Customer Feedback

In response to new materials, processes and requirements, Standard Tools & Equipment is constantly working on new products including: spray booths, frame machines, dust collectors, and all types of accessories. We are a lean, direct supplier with the ability to respond quickly to new demands and we always welcome any type of input from our product users.

At Standard Tools & Equipment our business is based on fulfilling the needs of our customers. Our customers work hands-on in the world of collision repair, painting, powder coating, and other industries. They are some of the most creative and knowledgeable people in their fields. Everyday they experience new materials, processes, and challenges.

If you are in need of a special product or have any suggestions, please contact our sales or engineering staff. Standard Tools & Equipment greatly appreciates your input and we look forward to exceeding your expectations.

Dust Collection Safety

A recent posting by the National Fire Protection Agency (NFPA) stated that the 2006 Combustible Dust Hazard Safety publication reported 281 major dust explosions with a total of 119 deaths and 718 injuries from 1980 to 2003. These incidents were due to the combustion of accumulated dust, unsafe dust mixtures, and other similar causes. Following this report there have been at least two explosions involving casualties. One explosion occurred at the Imperial Sugar refinery in Port Wentworth, Georgia, and another at a plastic molding plant in Kinston, North Carolina. To help prevent such industrial disasters, the NFPA is currently revising their combustible dust safety standards including NFPA-654 and NFPA-664. The United States Occupational Safety and Health Administration (OSHA) requires that combustibility information on all dusts encountered in a workplace be accessible to employees.

It is the employer’s responsibility to determine and apply the best methods to ensure safety in the workplace. These methods should include informing employees of the different types of dust materials present and how they are controlled. Standard Tools & Equipment provides products to aid in the management of powder coating, sanding/prepping, and woodworking. Our spray booths can be used for collecting sanding/prepping wastes and powder coat overspray. We also manufacture cyclone dust collectors that can be used to control dust, chips, and shavings created in woodworking operations. The cyclone dust collectors are best suited for small-to-medium shops, or for a limited number of machines in a larger shop. Using small collectors in a large shop reduces noise and energy consumption, as well as allowing more flexibility in shop layout.

For more information regarding combustible dust and workplace requirements contact OSHA.

Please contact Standard Tools & Equipment Co. at 1-800-451-2425 for pricing or product information.

Going Green in 2010

Today there is an increased awareness of protecting our environment from hazardous emissions and waste. Everyone is ‘Going Green’ to reduce these environmental pollutants. All types of companies are expected to address this matter, including firms operating spray booths. Spray booth operations can reduce waste in one of two manners: a dramatic overhaul of the entire process or incremental improvements.

Dramatic overhauls are expensive because they typically require intensive planning and resources. By focusing on the materials and equipment companies also bypass an opportunity to improve their employees and business processes. Production is almost always impacted during a change of this type and often afterwards. Even with an overhaul companies should not assume that all wastes will be eliminated.

Incremental improvements can be made in a manner that does not upset the production of a shop. These improvements can be started immediately and scheduled with available resources, government incentives, and production requirements taken into account. This is the process recommended by the Tools USA specialists.

Example of an Incremental Plan:

- Benchmark current operations: material types and volumes used, liquid and solid hazardous waste recorded, gaseous emissions calculated, hazardous operations noted, and level of operator knowledge

- Identify materials used to eliminate the most hazardous; many paint and solvent manufacturers now offer low-VOC options

- Evaluate solid and liquid waste by identifying waste source, retraining employees, mixing precise materials for jobs, and eliminating storage of excess material

- Understand gaseous wastes and new filter options

- Evaluate storage and spray guns

These steps require only a small investment and create a good foundation for future conversion to powder coating or waterborne paints and equipment. A shop that understands and addresses existing issues with incremental improvements will recover investments for major changes more quickly than a shop that makes only a dramatic change.

Please contact Kelly Goudy or the technical staff at Tools USA if you have questions about ‘Going Green’ with your spray booth operation.

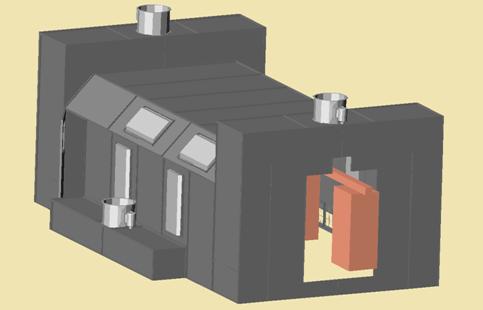

Pass-Thru Side-Down Draft Spray Booth

At Tools USA we routinely get requests for spray booths to be used on a conveyor line. Usually we will offer two opposed open-face booths or one of our designs with cutouts in the side walls. We have even made a spray booth to run lengthwise in order for the operator to stop/start the line when getting parts in and out of the DTD booth. Tools USA now offers a new booth style that mimics a larger-scale pass-thru booth using our SDD-1000 ETL and pressurized intake.

Pass-Thru Side-Down Draft Spray Booth (PTSDD-1000)

(shown with conveyer and parts simulated)

- Designed to be used with conveyer paint line

- Standard size suited to industrial parts: cabinets, furniture, housings, control boxes, carts, signs

- Wide enough for two spray operators for combined coverage

- Pressurized openings to prevent dirt/dust from entering spray area

- Uses air from exterior of shop (also works with heated air make-up unit)

- 4.8 air exchanges per minute (4.0 minimum required by OSHA and NFPA)

- Two personnel doors

- Eight Class 2/Div II lights

- Unobstructed ceiling allows exterior support of conveyer line if necessary

- Popular custom features: size of openings, size of booth, # of lights, Class 1/Div II lights, powder coated booth

- Can be set up as powdercoat booth with HEPA filters to recycle in-shop air

For further information contact Kelly Goudy at Tools USA

Phone: 1-800-451-2425

Email: KellyG@standardtool.com

Tools USA In-House Financing!

Tools USA has a new in-house leasing program for spray booths, frame machines, or multiple item purchases. To qualify, a prospect must meet the following criteria:

- Acceptable personal credit.

- Minimum 40% down payment.

- Located in eastern or central time zones.

- Agree to ACH monthly payment drafts.

Customers will be able to choose 24, 36, or 48 month lease options. Tools USA rates will run between 10 and 14%. All leases will be $1 buy-out financing leases.

The minimum financed after down payment is $3,000 (original price of item or items will be $5000).

An application can be requested by calling 1-800-451-2425.

When Should Spray Booth Filters be Changed?

Filters are often overlooked when evaluating the performance of a spray booth. A filter is a relatively inexpensive component of a spray booth and should be changed when necessary. Changing filters will help in avoiding poor finish jobs and unsafe conditions caused by inhibited air flow which can build toxic and combustible fumes.

Intake – Change filters when they fill with dust and dirt. Many auto body shops will change filters every two to four weeks if the booth is used daily.

Exhaust – Paint arrestor filters need to be changed under the following conditions:

- When the material being sprayed may react with something that has already been sprayed with these filters so as to create a toxic or spontaneous event.

- The static pressure differential is 0.5” or greater. This differential is measured on the manometer and is based on an empty booth with clean filters. Once the static pressure is above the basis line (0.5”), the exhaust filters need to be changed.

- Powder coat filters can be vacuumed many times and usually last 500-1000 hours.

Please contact Tools USA for information on spray booth filters or to order replacement filters.